The method of corner welding affects both the aesthetic value of the window and the functionality of the structure. The traditional method of connecting profiles is associated with, among others with the need to remove the flash. The latest V-Perfect technology enables to obtain a smoothly finished welding spot that retains its impeccable appearance for years.

The traditional way of welding PVC profiles

The disadvantage of the traditional method of joining corners is the need to remove the flash, i.e. the excess material flowing out during the profile welding process. There is no veneer in the place where the welded elements are joined – after getting rid of the excess. Accordingly, a profile is visible in the bonding area. To get rid of this cosmetic defect, special markers of a color similar to the color of the veneer are used. Unfortunately, they are not a perfect solution and start to wear off after some time. Additionally, this method of joining profiles makes the corners get dirty faster. This is due to the need to remove the flash by milling. This activity results in the appearance of pores invisible to the naked eye, into which impurities enter. Compared to the traditional method of joining PVC profiles, the use of robots is a much better option Graf Synergy SL4-FF EVO for flashless corner welding.

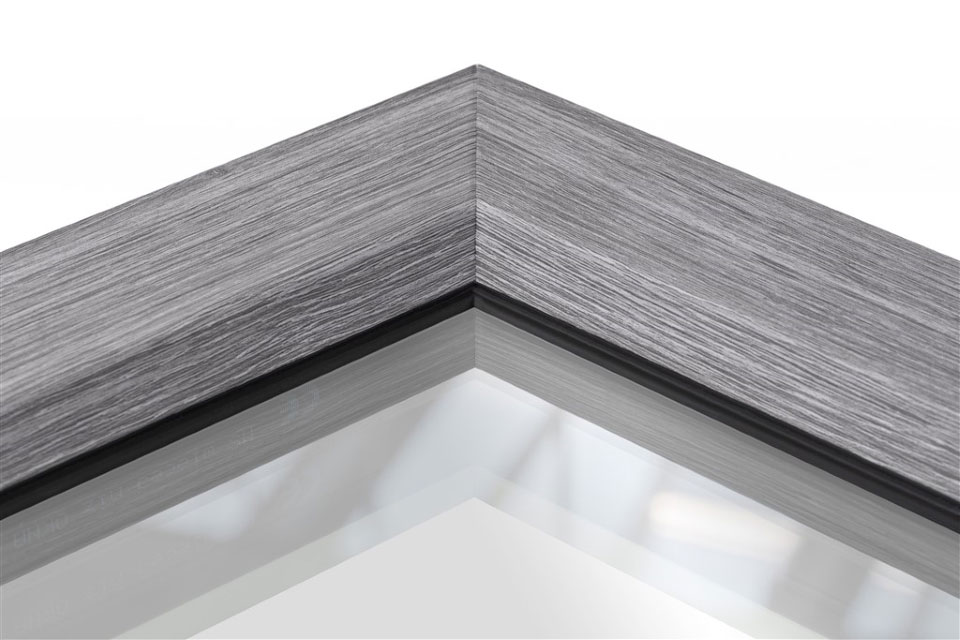

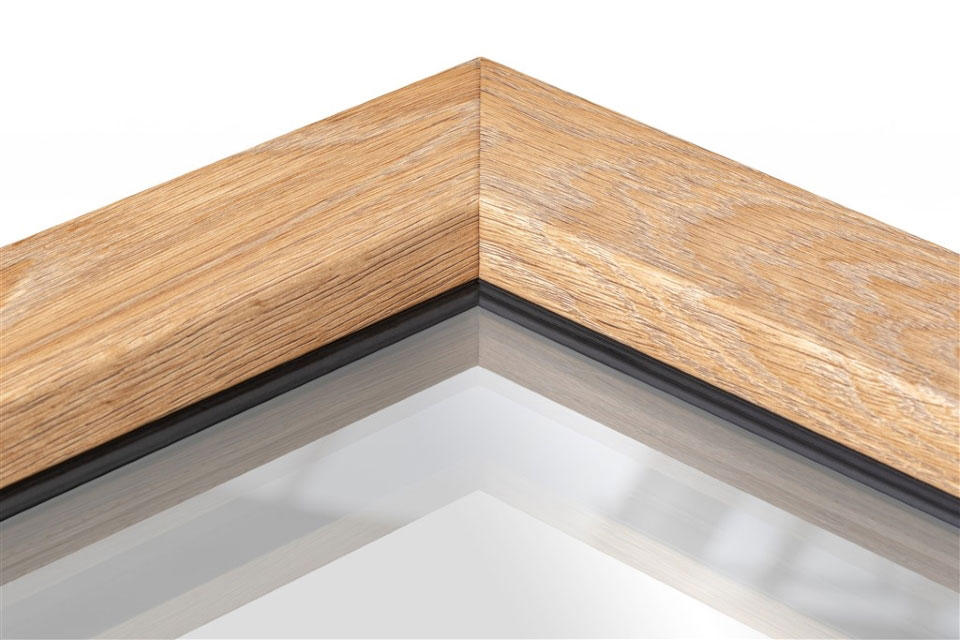

The welding effect is shown in the photos below.

Flashless welding – advantages

Profiles welding with the use of Graf Synergy SL4-FF EVO robots enables a delicate V-Perfect groove to be obtained. The use of this flashless method prevents excess material from flowing out of the bonding area. In the place where two elements are joined, the foil is kneaded. This allows you to mask minor unevenness of the profiles and ensure appropriate aesthetics also with thin, delicate veneers. The use of this method also makes it possible to partially mask the effect of foil shining in the area of the weld. Using flashless welding makes the corner of the frame or sash smoothly finished. Undoubtedly, this has a positive effect on the aesthetic value of the window. It is also worth mentioning that the V-Perfect technology has a positive effect on the tightness of the structure. Due to numerous advantages, Graf Synergy SL4-FF EVO robots are used in the production of windows available in MS offer more than WINDOWS .

V-Perfect technology in MS more than WINDOWS

Flashless welding is one of the newest technological solutions used in the MS more than WINDOWS factory. Graf Synergy SL4-FF EVO robots are used to connect the corners. The four-head welding machine enables flash-free joining of frames and wings. This process does not require the use of an additional device – a cleaner. Due to the fact that there is no need to perform additional mechanical processing, the result of the robot’s work is a finished window element. In addition, traditional “V” cleaning (white profiles) and ContourLine welding are also used.

The welding process of Graf Synergy SL4-FF EVO robots is presented in the video:

ContourLine technology

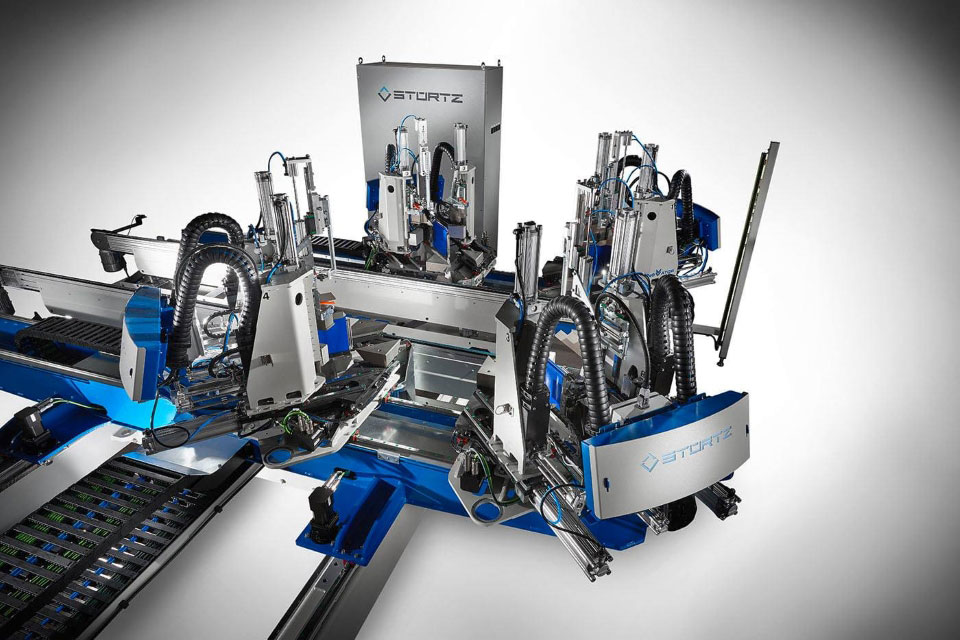

The welding process in MS more than WINDOWS is carried out not only with the use of Graf Synergy SL4-FF EVO robots. The machine park was supplemented with a modern welding and cleaning line TURBO T-DRIVE. It carries out the process of joining profiles using the ContourLine flashless welding technology and the OpticTwinStar double head cleaning machine. It is worth emphasizing that MS more than WINDOWS is the only company having a Stürtz machine in such a configuration. Interestingly, this device allows you to produce windows also in traditional technology, i.e. with flashing. ContourLine, on the other hand, achieves the same aesthetic effect as with the V-Perfect method. One-sided veneered windows are welded using this technology MSline and MSline + AD . Contrary to the Graf Synergy SL4-FF EVO process, the surface of the elements is not milled before heating. TURBO-T-DRIVE is equipped with special knives that remove the flowing material while heating the profiles. Then there is pressure and an aesthetic weld is formed. The TURBO T-DRIVE line is presented in the photos below.