The functionality and properties of the front door are influenced by both the materials used and the course of the production process. High-quality construction is ensured by m.in. and making profile processing on the CNC processing centre. Thanks to them, the entrance doors available in the MS offer more than windows are characterized by high rigidity and accuracy of workmanship.

Steel processing on CNC

The profiles used for the construction of the entrance door are machined using the CNC machining centre. The processes by which lock pockets are created are performed on steel reinforcement elements. Importantly, in MS more than WINDOWS tools are cooled with cold air. This not only extends their service life, but also has a positive effect on the quality of the treatment carried out.

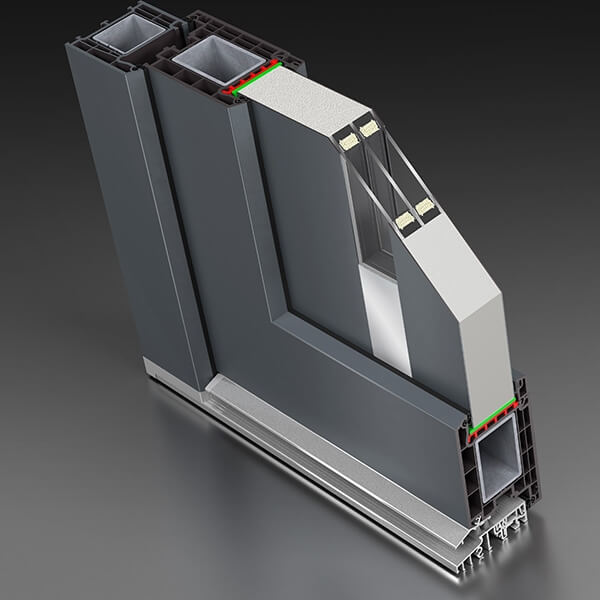

Steel reinforcement 3 mm

In the wings of the door profiles there are steel profiles measuring 60×40 mm, the thickness of which is 3 mm. Thanks to them, the design is characterized by proper rigidity. The strength of the entrance door is also positively influenced by the presence of a steel reinforcement enclosed in the frame (2 mm thick).

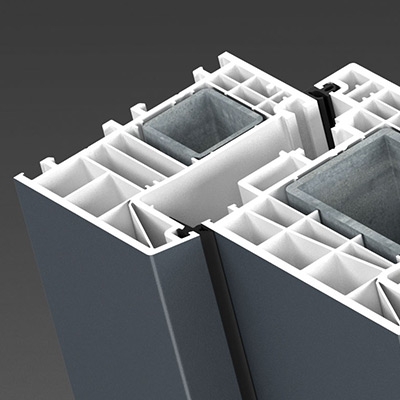

Bones, weed, for door profiles

The appropriate parameters of the door profiles can be achieved by using weaning bones. These elements are used to strengthen the corners of the wings during the welding process. They are deposited in the reinforcement for better corner strength. This solution increases the area of the weed. Moreover, it allows for a longer gain. Thanks to the weed bones, the steel is cut at an angle of 45° and reaches the end of the profile.